Over the years, Northspan has counted among its clients both major and junior mining and exploration companies. No matter whether a project is big or small, we will work with our clients to provide the best solutions, quality and service. At Northspan, we take every drill program personally!

Below are a select few of our most recent clients and their projects where Northspan's drills have been put to the test.

Aurora Geosciences Ltd.

“

We have been operating in the North for over 35 years. Our experience with Northspan Explorations Ltd. has been with using their reverse circulation till sampling expertise and the small Hornet drill. This particular unit is easily heli-portable and very efficient. The gear was well maintained. Their crews were motivated and extremely professional.

Northspan bases its operations from Kelowna, BC with very high best practices in our industry. Their knowledge and understanding of field operations allows us to provide services to our clients that exceed industry standards for drilling operations. We could not be more pleased from our experience with Northspan.

”

Gary Vivian, M.Sc., P.Geol

President

Kaminak Gold Corporation

“

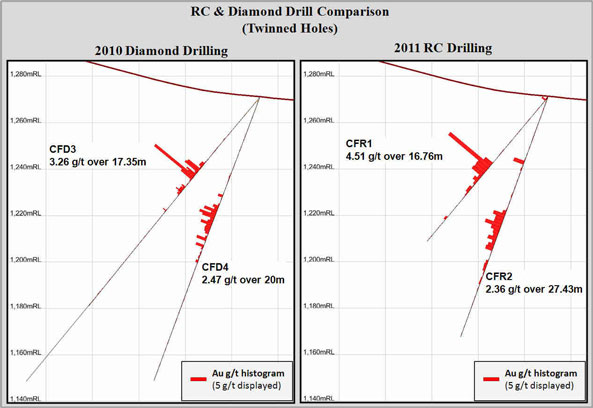

The first boxes of core drilled in 2010 at our Coffee Gold discovery, Yukon Territory, suggested to me that the property was amenable to RC drilling, and despite the Canadian exploration industry relying almost exclusively on core drilling I was very happy to find a Canadian company that specializes in fit for purpose fly-, track- and skid-mounted RC.

We tested Northspan’s drilling systems by twinning existing core holes and quickly concluded that the reliability surpassed expectations for exploration and in fact the drill holes and samples derived are suitable for resource estimation purposes.

Over the past four years we have proudly demonstrated the effectiveness of RC drilling at the Coffee property to numerous visiting geological consultants and resource analysts, and converted all to the efficacy of Northspan’s RC systems along the way.

There is no doubt that RC drilling completed by Northspan at Coffee over the past four years, at significantly increased rate of production and cost saving compared against core drilling, has had a tremendous impact on the pace of discovery and resource growth at the Coffee property, which currently stands at 4.1Moz gold, and ultimately in the positive scoping study of what we hope will be Yukon’s next gold mine.

”

Tim Smith MSc P.Geo.

Vice President Exploration

Peregrine Diamonds

“

The Northspan crew and the Hornet RC fly-drill provided a versatile, reliable, safe and very cost-effective drilling solution to Peregrine’s Chidliak project in 2014. We worked a single-shift roster under Winter/Spring and Summer conditions, and completed around 1,350 m in 91 holes in 40 working days with near-zero downtime in applications spanning resource delineation, overburden mapping and exploration target testing. One particularly inspiring outcome is captured by the photo: four hours of drilling on a speculative step-out hole proved “blind” kimberlite at about 50 m depth and that an approximately 25% expansion of kimberlite pipe volume was “in play”. What a pleasure!

”

Herman Grutter, Ph.D., P.Geo.

Program Manager, Chidliak Exploration

Fission Uranium Corp.

“

Fission Uranium’s Patterson Lake South Project (PLS) is the most exciting uranium discovery in recent years in Canada’s Athabasca Basin, which is host to the richest producing uranium mines in the world. The PLS project hosts the spectacular Triple R high-grade uranium deposit, which is located at a shallow depth. The project presents certain drilling challenges as the deposit is overlain by 50 m of gravel and boulder-rich overburden. In addition, much of the deposit is located beneath Patterson Lake. Historically, drilling in the Western Athabasca region has been challenging with many drill holes failing to reach target depths. In particular, the success ratio of angled drill holes has been low.

“We required a drilling solution, which would increase the ratio of diamond drill holes successfully reaching target depths. Because of the orientation of the project geology, angled drill holes were needed. Furthermore, the company required a solution, which would prevent diamond drill cuttings and/or muds from entering the waters of Patterson Lake.

In answer to these challenges, Northspan designed and constructed the Attacus dual-rotary drill. Equipped with the latest in water hammer technology and casing advancer systems, the Attacus drill successfully pre-collars holes by inserting casing through the overburden beneath Patterson Lake.

This allows diamond drilling to proceed rapidly with over 95% of drill holes reaching target depths. In 2013-14 more than 200 vertical and angled holes were completed, helping our technical and management teams advance the project at a pace rarely thought possible in the Athabasca Basin. The pre-collaring carried out with the Attacus drill complements the diamond drillers of Bryson Drilling Ltd. as they drill this spectacular deposit without drill cuttings or muds reaching the waters of Patterson Lake.

It is a pleasure to work with Northspan. They are an innovative company that continually improves its drilling methods and equipment with a focus on environmental stewardship and efficiency.”

”

Raymond M. Ashley

VP Exploration