What is RC drilling?

Reverse circulation (RC) drilling uses a bit attached to a down-hole hammer to produce a hole. Unlike diamond drilling, RC drilling produces samples of rock cuttings rather than a sample of rock core. The down-hole hammer is powered by compressed air, which also acts as the medium bringing the drill cuttings up to surface.

Big and bulky? Not anymore. Northspan brings the benefits of RC to the remote regions of Canada.

Traditionally, RC drill rigs have been known as powerful, heavy truck- or track-mounted machines. Such machines are unsuitable for remote exploration work because of the difficulties and costs associated with moving the drills to site. In Canada, Northspan has changed this by being a front-runner when it comes to designing RC drills, which can be moved to remote drill sites with light helicopters (such as a Bell 206L) or fixed-wing aircraft (Twin Otter).

Reliable samples

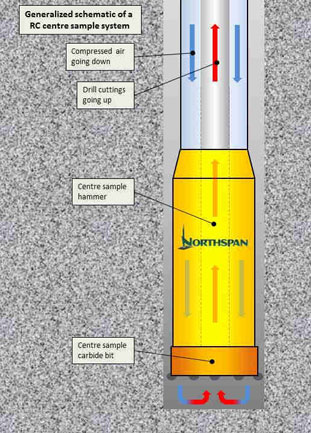

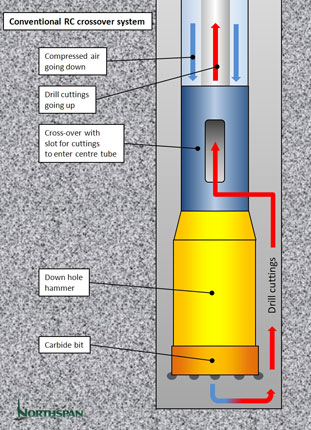

RC drilling today produces samples of high quality and reliability. Dual-pipe RC drilling utilizes double drill rods where air is passed down the hole through the outside annulus and into the hammer. Drill cuttings are cleared from the bit by the air and travel up through the centre tube of the drill rods remaining free from contamination.

There are two main types of RC drilling systems: the centre-sample system and the conventional cross-over system. Using the centre sample system (see schematic), drill cuttings liberated by the bit travel up directly through holes in the bit face and into the centre tube of the drill rods. This method produces an accurate and uncontaminated sample. As a result, RC drilling results are successfully used in compliant (NI 43-101, JORC) resource calculations worldwide.

When using the conventional cross-over system (see schematic below), cuttings first travel up around the bit before entering the centre tube through cross-over slots. This method is rapid, cost-effective and particularly suited for first pass exploration drilling.

In a number of geological scenarios, the large volume of sample collected by RC systems can be a significant advantage. Exploration projects dealing with a “nugget effect” (for example, coarse gold or diamond projects) can often benefit from a larger diameter drill hole. Northspan generally drills holes with a diameter ranging from 3 ⅝” to 4 ½” (92 mm to 114 mm). The sample recovery from a 3 ⅝” (92 mm) diameter hole is approximately 11 lbs/ft (16.4 kg/m) depending on rock type.

RC is a drilling method widely used around the world. The method is unbeatable in areas where water is scarce or expensive, such as Australia and Western Africa (and, for the same reason, in northern Canada).

High rate of penetration

A big advantage of RC is its high rate of penetration. Penetration rates often exceed 80 m per shift depending on ground conditions. The speed of drilling can often mean big cost savings compared to slower drilling methods.

Good in bad ground

RC drilling is relatively insensitive to ground conditions, which may be difficult or slow to penetrate using other methods. Dual-pipe RC was originally developed as a method to drill “nightmare” geological formations (such as permafrost, glacial till, broken rock, etc.) where conventional drilling methods were costly and ineffective.

RC drill cuttings are transported to surface inside the centre tube of the dual pipe. Because of this sample recovery is usually very good with high recoveries of both fines and clays.

Environmentally sound

Reverse circulation drilling has several environmental advantages. First and foremost, RC mostly requires no water for rock drilling. This is a benefit in areas with limited or sensitive water supply.

In addition, frozen water sources and waterlines can make winter drilling both tricky and expensive, if not impossible. In certain areas, like the arctic tundra, environmental permitting is easier for winter drilling when the ground is frozen and unlikely to be disturbed. Light-weight RC makes winter drilling in the arctic a viable option.

Why not carry out land-based winter drilling programs as opposed to more expensive heli-supported summer programs?